productgroups

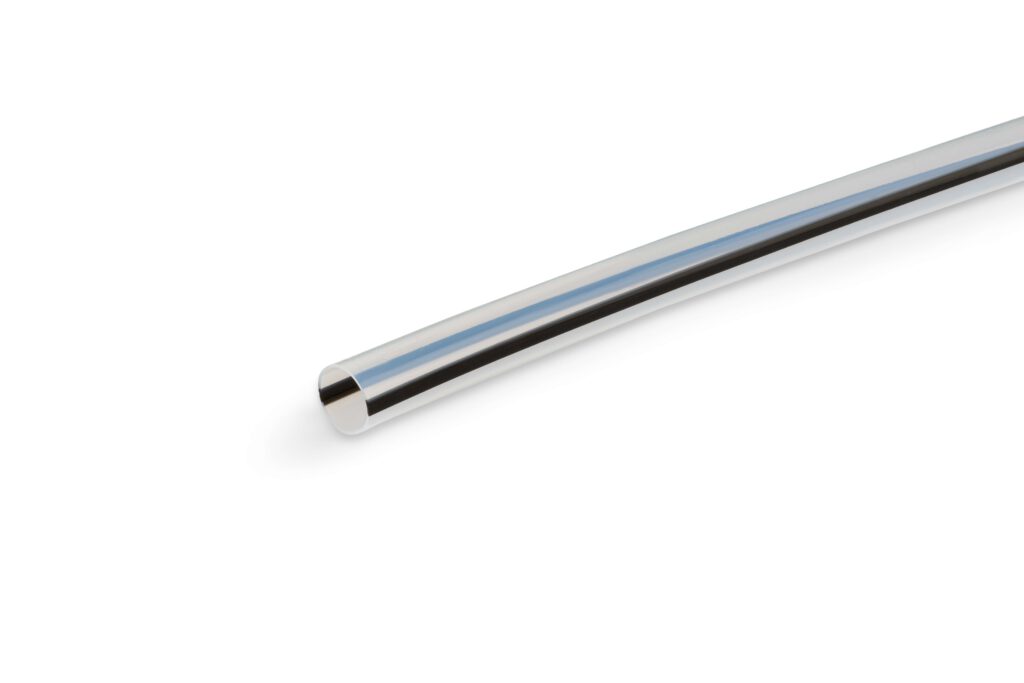

Smoothbore

PTFE Tubing

PTFE tubing with smooth ID and OD. Available in almost any combination of ID, wall and OD. From less than 1 mm. To 200 mm diameter, wall from 0,1 mm to 5 mm. Used in a variety off applications, excellent chemical- and temperature resistance. Unrivalled electrical properties.

Non-stick and extremely low friction coefficient. Available in colors, with various fillers and antistatic or conductive properties. Stock sizes available as listed in appendix.

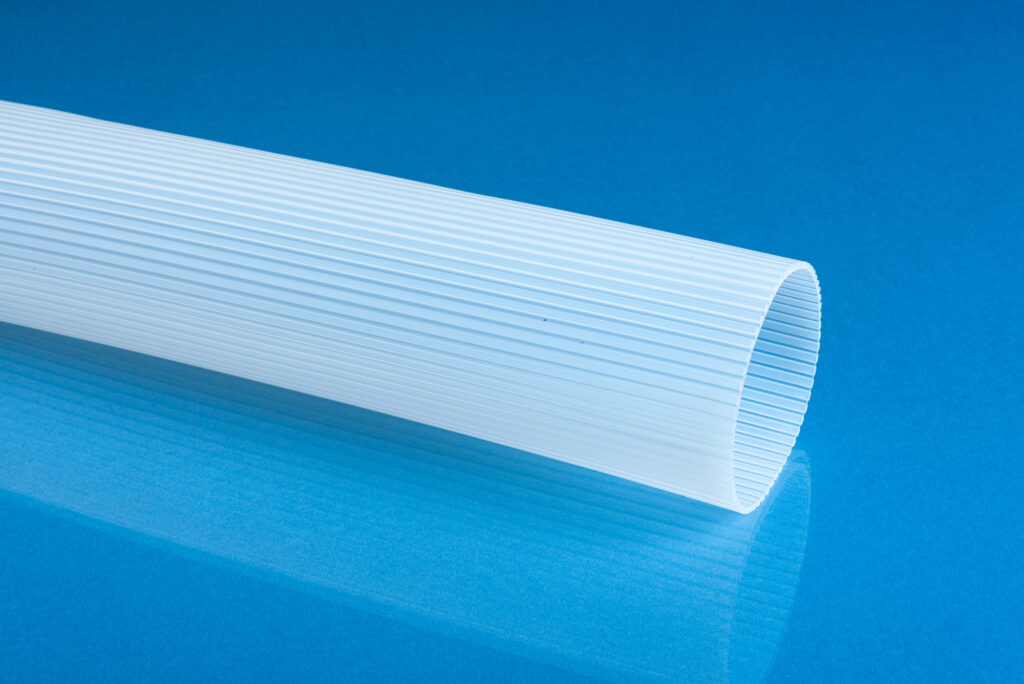

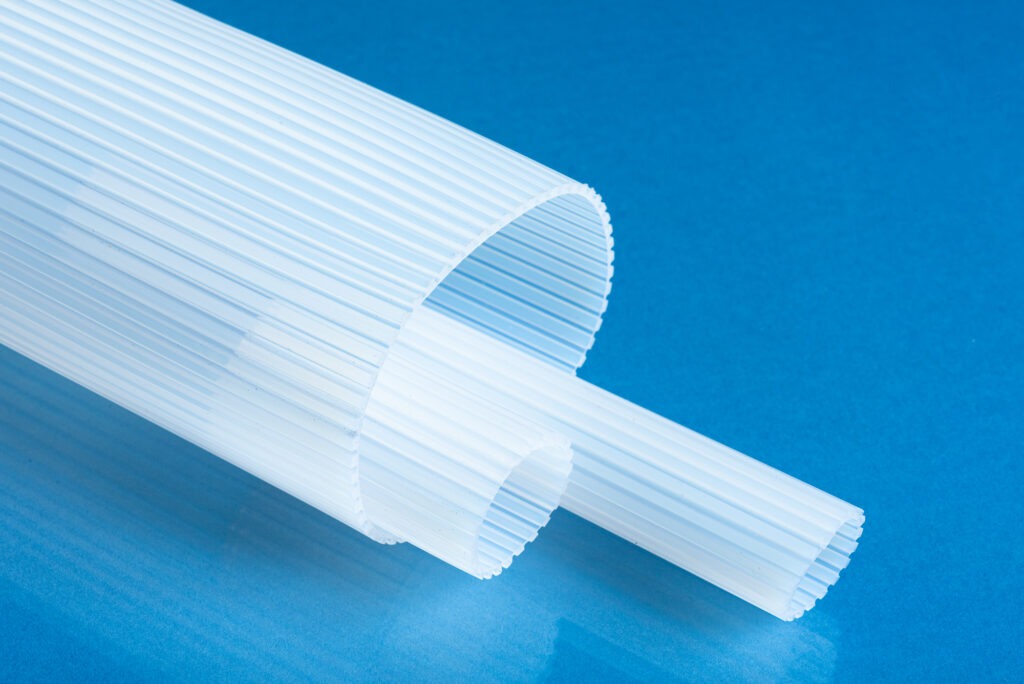

Convoluted PTFE Tubing

PTFE tubing with convoluted ID and OD. Extremely flexible and high kink-and vacuum resistance. FT offers standard ranges of Low convoluted, Heavy wall and extra heavy wall tubing, sizes from ¼” up to 6” Bore.

Antistatic, conductive and Conductive striped tubing of each standard item are available. Non-standard sizes can be designed and manufactured upon request.

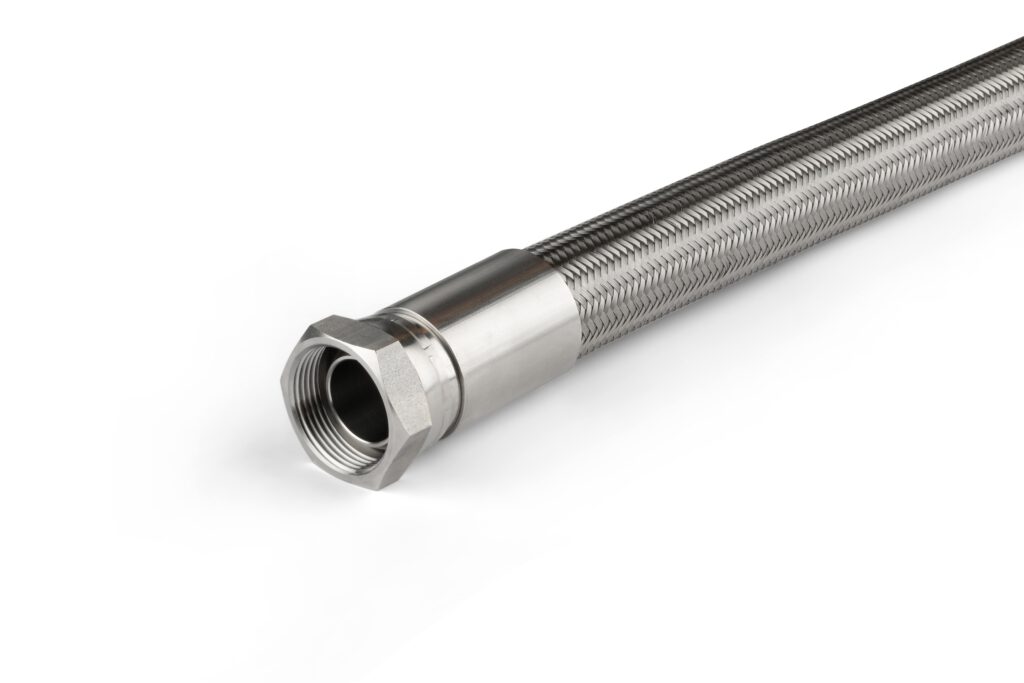

Convoluted Braided PTFE Tubing

Purpose of Natural Convoluted SS Braided Hose

This general-purpose hose is meticulously designed to meet a broad range of application requirements. It features a high-tensile grade 304 stainless steel wire braid, providing maximum protection against internal pressure and external abrasion. A stainless steel 316 braid is also available upon request for applications requiring additional resistance to corrosion.

Optional: Polypropylene, PVDF & Aramid Braid

Purpose of Antistatic Convoluted SS Braided Hose

The AS grade is crucial in applications where there is a risk of electrostatic charge build-up on the PTFE tube’s inner surface, which could discharge through the tube wall.It is essential for handling:

• Twin or multi-phase media

• Non-mixing media (e.g., powder in air, water droplets in steam, gases, or oil)

• Colloidal fluids

These conditions pose a significant risk for static charge generation and always require the AS grade hose.

Fluor Flow®️

Purpose of Natural Fluor Flow SS Braided Hose

This general-purpose hose, featuring a smooth inner surface and a corrugated outer surface, is meticulously designed to enhance product flow rates and improve cleanability. The high-tensile grade 304 stainless steel wire braid offers maximum protection against internal pressure and external abrasion. A stainless steel 316 braid is also available upon request for applications requiring additional resistance to corrosion.

Optional: Polypropylene, PVDF & Aramid Braid

Purpose of Antistatic Fluor Flow SS Braided Hose

The AS grade is crucial in applications where there is a risk of electrostatic charge build-up on the PTFE tube’s inner surface, which could discharge through the tube wall. It is essential for handling:

• Twin or multi-phase media

• Non-mixing media (e.g., powder in air, water droplets in steam, gases, or oil)

• Colloidal fluids

These conditions pose a significant risk for static charge generation and always require the AS grade hose

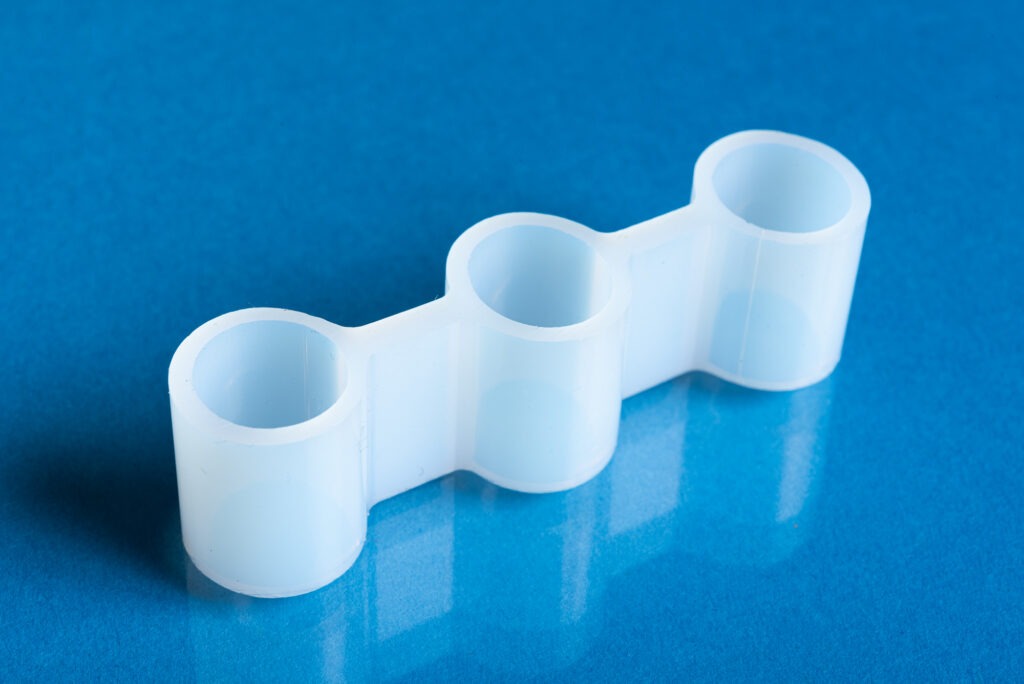

PTFE extruded Profiles

Hollow or solid, single and multi lumen, any profile within a size range of 1-100 mm. OD and wall thickness of 0,1- 5 mm. can be extruded. FT offers mold engineering and production. Colors /fillers are possible.

PTFE Extruded Films

FT is one of the few manufacturers in the world to make PTFE extruded, sintered Films in Modified PTFE. Width up to 600 mm, thickness 1-2 mm. For bonding purpose, the films can be etched, single- or double sided with sodium in ammonia . Excellent flex life. High transparency. Superior weldability. Isotropic films are optional.

Blow molded PTFE shapes

PTFE tubing shaped to its final form in one single process. Ensuring high repeatability and high efficiency. A suitable process for large series of tubing shapes for use in OEM . Product size from 5 to 300 mm. diameter. FT offers mold engineering and production as well as the complete product. Robot welding with PFA wire /cap and pressure welding is available to make complicated products.

PTFE MemBranes

Fluortubing produces membranes made from modified PTFE that are unique for their untmatched flexlife, smoothness and low permeation rates. Membranes can be shaped to suit almost any design pump or valve.

In addition Fluortubing can provide single or double sided Sodium Ammonia etching to enable adhesion of elastomer backing or glueing to various surfaces. Membrane thickness 0,5 - 2,5 mm, diameters up to 600 mm.